Testing

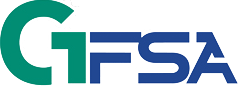

Flow Testing

High pressure flow testing provides the means to test performance criteria of safety critical equipment at elevated, real-world pressures. It also enables identification of areas where design changes could be made to the test item to further improve operational performance.

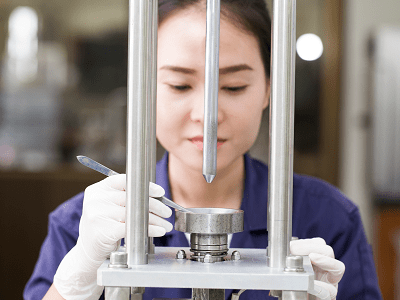

Specialised Mechanical Testing

Mechanical testing encompasses a range of tests that measure the properties of a material by observing how it reacts to a force being applied to it. Mechanical testing is crucial to ensure a component complies with specification requirements and is safe, of compliant quality and fit for purpose. GFSA utilises a number of NAMAS accredited laboratories to address the mechanical testing requirements of our clients (on a project specific basis).

Non-Destructive Testing

Non-Destructive Testing (NDT) methods can detect surface and sub-surface defects without affecting the operating performance of the inspected products. GFSA perform NDT on metals and alloys, including tubing, pipes, bars, plates, castings, fasteners, etc. NDT Weld Testing methods are also offered to inspect the quality of welds.

We can provide Hydrostatic Pressure Testing, also known as Hydro Testing or Leak Testing, up to 1600 bar (23,206 psi). This provides a method for finding leaks or verifying performance and durability in pressure vessels. The hydrostatic pressure test is classified as a Non-Destructive Testing technique as the sample is typically not harmed during testing.

GFSA has relationships with local NDT operators who carry out Ultrasonic Testing (UT) services on our behalf, this can be performed to locate discontinuities in material and welds, and inconsistencies in tubing and pipe wall thickness.

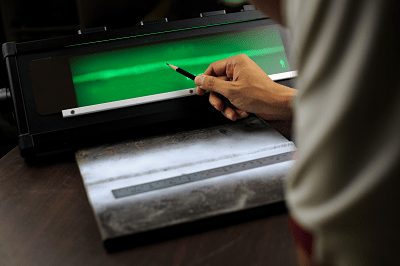

Surface and near surface discontinuities can be identified in products that can be magnetised using Magnetic Particle Inspection services. Wet fluorescent Magnetic Particle Testing is performed using equipment with a maximum output of 6,300 amps. Dry powder inspection services can be also provided.

Liquid Penetrant Testing is reliable for detecting surface-breaking flaws in materials with a non-porous surface. Dye penetrant testing can use both fluorescent and visible dye on products.

GFSA works with local NDT operators to offer X-Ray based non-destructive testing which can be used to locate internal discontinuities, verify the integrity of internal components and determine the quality of welds. It can even penetrate thick metal and parts.