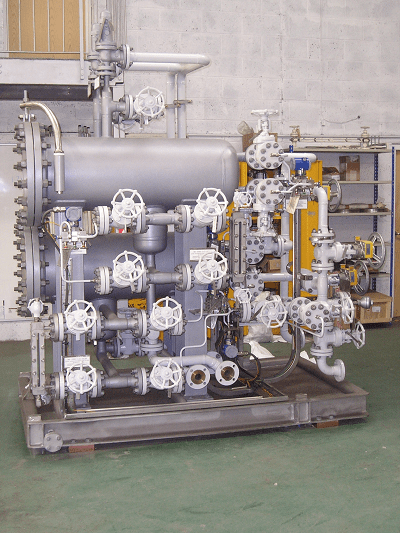

Separators / Coalescers

GFSA Liquid-Gas Coalescers (Separators) are primarily used within the Oil & Gas industry for removal of water or hydrocarbon condensate. They maintain natural gas quality and protect downstream equipment such as compressors, gas turbines, amine or glycol absorbers, molecular sieves, PSA's, metering stations, mercury guard beds, gas fired heaters or furnaces, heat exchangers or gas-gas purification membranes.

In the Natural Gas industry, gas/liquid coalescers are used for recovery of lube oil downstream of a compressor. All liquids will be removed but lube oil recovery is the primary reason for installing a coalescer on the outlet of a compressor. Liquids from upstream of the compressor, which may include aerosol particles, entrained liquids or large volumes of liquids called "slugs" should be removed by a filter/coalescing vessel located upstream of the compressor. Slugs may consist of water and/or a combination of hydrocarbon liquids. Efficiencies of gas/liquid coalescers are typically 0.3 Micron liquid particles, with efficiencies to 99.98%.

GFSA Inline Coalescers are mechanical devices for the separation of solids and liquid contaminants from the process fluid by means of coalescing cartridges and stripper cartridges, both of which are housed and secured within the coalescer body. The filter will also contain a large knock out section in the bottom of the vessel, this section will capture the liquids or hydrocarbons. The inlet nozzle can also be supplied with a bespoke inlet device which can aid stripping of the gas and removal of liquid droplets. The location of the tube sheet and filter cartridges is carefully designed to prevent any re-entrainment of liquids.

Filter Coalescer elements are located in the upper compartment of the vessel. As Inline Coalescers are single integral pieces of equipment with no moving parts, they do not require any external operational procedure. The exception is where DP indicators and/or transmitters are fitted. In this case regular inspection should be made in order to monitor pressure differentials across the equipment. Where DP indicators and/or transmitters are fitted reference should also be made to the respective manufacturer’s instructions for operation and maintenance.

Liquid-liquid coalescers can be used to separate hydrocarbons from water phases such as oil removal from produced water; these separators work by gravity and can be sized using Stokes Law. Separation and sizing can be enhanced by the inclusion of bespoke vessel internals which can aid coalescence by promoting the growth of water molecules which are more easily collected by gravity.