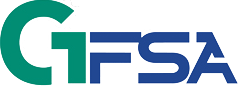

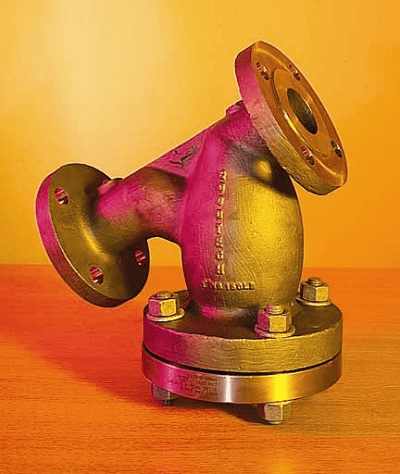

Y-Type Strainers

Y-Type strainers are classed as a permanent strainer of a Y-configuration consisting of an integral cast, forged or fabricated body housing a cylindrical strainer element which is usually called a “screen”. The screen is located within the Y-pattern body and access is via a branch cover. T-Type Strainers can be installed both in the horizontal and vertical positions without any effect on performance providing the screen is installed in the downward position to assist draining and cleaning operations.

Y-Type strainers are very versatile and are used in a wide range of applications where protection of major capital equipment is required such as pumps, flowmeters, control valves, steam traps, heat exchangers, chillers, spray nozzles, relief valves and regulators.

Two types of cover are available on standard GFSA Y-Type strainers:

- Bolted

- Increased Safety Cover

The increased safety cover was primarily developed for the gas industry and prevents the cover from being removed before the unit has been vented and all internal residue pressure removed, providing the optimum in operator safety.

Sizes range: From ½” (15mm) to 2” (50mm) n.b. for forged units, ½” (15mm) to 14” (350mm) n.b. for cast units and 1” (25mm) to 24” (600mm) for fabricated units.

Pressure ratings: Available from 125LB to 2500LB

Flange facings: Wide selection of flange specifications and facings.

Line connections: Available as screwed, socket-weld, butt-weld and flanged.

A wide selection of materials available including:

- Cast Iron

- SG Iron

- Carbon Steel

- Low Temperature Steel

- Heat Resisting steel

- Various grades of Stainless Steel, Gunmetal, Aluminum Bronze, Cunifer (90/10), Duplex and Super Duplex Stainless Steel, 6Mo Stainless Steel, Alloy 20, Alloy 28, Inconel, Monel, Hastelloy and Titanium.

Optional features can be accommodated to most units and include:

- Magnetic inserts

- Special gaskets

- Differential pressure connections

- Special screens

- Flanged drain connections

- Certification to 3.1 / 3.2 / NACE

- Valve drain connections

- NORSOK

- Special coatings and linings