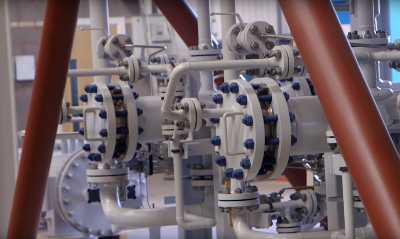

Self-Cleaning Strainers

GFSA Self-Cleaning Strainers are an alternative to Duplex Strainers in that they allow cleaning of the filter element without interrupting the process flow. One significant difference, however, is the added benefit that the element does not have to be removed for cleaning. The cleaning operation is carried out within the unit, thus reducing maintenance and increasing economy.

In Self-Cleaning Strainers, the cleaning action is centered around a specially designed filter element which utilises a flat non-clogging outer edge onto which contaminates build up. This element is rotated either manually or automatically against a fixed spring loaded wiper blade incorporating a unique PTFE replaceable insert. Contaminant build up is removed from the outer edge of the element and falls under gravity to the sump of the unit. Contaminant is removed from the unit by opening and closing a manual or automatic drain valve.

The GFSA PTFE insert blade assembly only requires the insert to be changed, not the complete assembly, as with some inferior designs on the market. This operation can be carried out within seconds by just a simple quarter turn of a lever, without the need of special tools.

Units are available as manually operated or with varying degrees of automation and instrumentation subject to customer requirements. The most common mode of automation is when the cleaning cycle is initiated by a differential pressure switch which monitors the pressure differential across the inlet and outlet of the filter. When the pre-set cleaning pressure is obtained the cleaning cycle commences.

Advantages and special features of GFSA Self-Cleaning Filters:

- ‘V’ shaped wedge wire elements exhibit non-clogging properties.

- Multi-elements can be provided to include high open area.

- Small multi-blades prevent distortion experienced with single long blades.

- Blade assembly can be tensioned and untensioned without dismantling the screen assembly.

- Blade assembly is tensioned the whole length, not just ends like some inferior designs on the market.

- No special tools required.

- Replaceable PTFE blade insert reduces spares costs, no need to replace the whole blade assembly.

- PTFE blade insert reduces the possibility of static build up which can be potentially hazardous in flammable environments.

- Low co-efficient of friction between wiping surfaces reduces operating effort and power requirements.

- Elimination of backwashing promotes continuous on-line operation with minimum fluid wastage.

Size range: From 1” (25mm) to 6” (150mm) n.b. and up to 24” (600mm) n.b.

A wide selection of materials available including:

- Cast Iron

- SG Iron

- Carbon Steel

- Low Temperature Steel

- Heat Resisting Steel

- Various grades of Stainless Steel, Gunmetal, Aluminum Bronze, Cunifer (90/10), Duplex and Super Duplex Stainless Steel, 6Mo Stainless Steel, Alloy 20, Alloy 28, Inconel, Monel, Hastelloy and Titanium.